|

| |||||||||||||||||||||

| |||||||||||||||||||||

| |||||||||||||||||||||

| |||||||||||||||||||||

| |||||||||||||||||||||

Welcome to another issue of Archimedia, the System Thinking and Constraints Management newsletter brought to you by:

The Theory of Constraints Centre of Australia (TOCCA).

Click Here to Subscribe!

The Knowledge Capital Reporting Awards

David Hodes presenting the Inaugural Award for

Knowledge Capital Reporting to Ian Ward - Westpac

The Knowledge Capital Reporting Award is a new award introduced this year to recognise excellence in reporting on the management of the intangible capital and knowledge intensive resources within an organisation. The TOC Centre of Australia is a major sponsor of the ARA and is the Sponsor of this Award.

See David Hodes’ Speech for the AR Awards

TOCCA gratefully acknowledges the assistance provided by The Society for Knowledge Economics in the adjudication of the submissions.

From the Field: BHP Billiton Iron Ore

Critical Chain in large Infrastructure Projects:

Productivity improvement of more than 33%

Engineering work finished 3 weeks ahead of tight schedule

In our Archimedia newsletter of December 2005 we told the story of how Critical Chain was being used by the Asset Development Projects (ADP) Group of BHP Billiton Iron Ore (BHPBIO) to take advantage of the latest innovations in the execution of large, complex projects. Initially, the use of the Critical Chain method and the supporting Concerto tool was limited to the Controls Engineering group of their EPC Contractors, the MPDJV – a joint venture between two leading engineering and construction companies, SKM and Fluor.

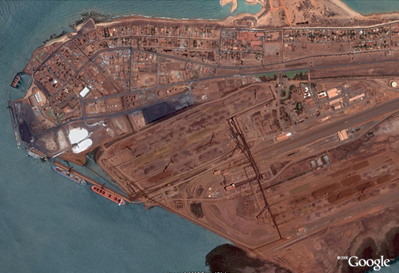

BHP Billiton mine iron ore at various sites in the Pilbara region of WA and export product through their facilities at Port Hedland. Those facilities have operated since the late 1960’s and have continuously been upgraded and expanded.

A potential “drum" or bottleneck resource of these port operations has been the Car Dumpers. These are the mechanical plant that dump the ore from trains with long rakes of ore wagons, or cars, that ply the railroad, hauling ore from the inland mine sites. In recent years, with the strong economic growth of China, demand has led to very substantial upgrading of the Car Dumper facilities. These have been a mix of upgrades to existing Car Dumpers and new construction.

This application of Concerto is about the engineering to allow the upgrade of the second Car Dumper, built in 1976, and in continuous operation since.

Car Dumper 2 is an automated plant capable of accepting 10,000 tonnes per hour from ore wagons, each carrying 120 tonnes. The wagons pass through the Car Dumper on rail track at ground level with three cars at a time rotated 145 degrees, emptying them into receival bins beneath. Below the bins, a steady flow of ore is established on apron feeders and this flow is conveyed out of the base of the dumper vault and up to a transfer station where other conveyors distribute the ore within the yard, or to waiting bulk carriers.

As the potential drum resource of the operation, the shutdown of Car Dumper 2 for its upgrade was scheduled very tightly, with a strong commercial imperative to minimise the timeout. Engineering, materials and equipment supply had to be tightly controlled in preparation.

The engineering of Car Dumper 2 upgrade held major challenges:

- Whilst a previous Feasibility Study had established a strong concept design and a budget to +/-15%, the Design Development and Detailed Design in an existing “brownfields” environment were bound to contain unforeseen complexity

- The detail of the existing concrete vault remained uncertain

- The full engineering, 25,800 budgeted man-hours of multi-discipline work, had to be completed in an eight month period

- The team assembled for the project had approximately one third new staff, some of whom were in key positions

- Engineering had to provide equipment scoping early for procurement purposes; as well as integrate equipment details late in the scope

- The work had to include for involvement of BHP Billiton operations to ensure safety of the design for operations, maintainability and availability for construction and commissioning

Based on previous Port multi-discipline designs, it was recognised that timely production of the engineering work at the detailed level would underpin the success of procurement of equipment and supply of materials, fabrication of steelwork, and detail planning for works on-site. Concerto was chosen to give this schedule focus to the engineering component of the work.

The work was planned into 25 Concerto “Projects”, mostly by physical scopes, each with a deliverables list of drawings. The general engineering process (a proven and stable process within the Port engineering team) was applied to each scope to develop the portfolio. This method ensured adequate engineering development time and eliminated most of the risk associated with the wrong disciplines working on the project too early. Inputs, such as Client reviews and equipment data supply were modeled. Milestones were added for delivery of early information that would allow commencement of other activities such as steelwork fabrication.

Concerto, when applied by the engineering team, provided a reference framework for the team to work to. It was particularly valuable for people working together for the first time. Short, regular planning review meetings, using the current Task List as an agenda, were held several times a week to keep team interaction at a high level. The meetings raised awareness of each discipline to the others, although there was some overlap with older style weekly engineering meetings.

Concerto kept all of the work scope in balance. It also continued to highlight new tasks that had to be commenced if the overall schedule was to be maintained. This obviously added to time pressure but kept it at a factual level.

Concerto proved flexible in coping with day to day change from issues and from work progress against the original plan. Where a task contained a problem that took longer to resolve than planned Concerto kept the task 'up in lights' as a high priority, whilst at the same time adjusting for the revised pace of work.

Concerto also allowed unforeseen issues to be absorbed and accommodated for in the plan moving forward. At least two of the packages were disrupted by detail technical issues. This meant that certain tasks were reforecast on a rolling basis, but Concerto took these time revisions to account in overnight rescheduling, allowing the team to continue to understand the time challenges day by day.

Concerto was, however, not without its struggles: for example, the discovery process of the real meaning of “buffer consumption”, and “my activities going red when I haven’t worked on them yet”; and subsequently the next level of informed behavior of trying to make it look good.

Concerto kept the end dates in focus. This was particularly relevant for the “following” or downstream disciplines such as piping and services, concrete and minor civils work and electrical.

The complete engineering work was finished three weeks ahead of the planned date. A more normal result is to have the last 5% of engineering being completed as the work is being built.

Work packages were mostly +/- one week of the planned dates with only three running to + one to + three weeks, these due to specific circumstances that were recognised and accommodated for.

A key element of the Concerto planning was to provide packages of work for steelwork shop detailers at regular intervals from approx 50% into the design period. In the first instance, Concerto helped create a clear focus on these dates and the work that had to be done to achieve the outcomes from each work package. The initial packages were delivered on time. One package subsequently ran four weeks late but the remainder, with one or two “trades” of work scopes, were on-time.

Given that this was the first full application of the Concerto package by the Port engineering team it has been a learning and exploring application. There are many details of the use of Concerto that need care: for example resetting of projects part way through. Effective planning of inputs and outputs to the engineering work has taken some time to establish. Management of drawing reviews and document checks, and the allocation of times and resources to these, also had to be formulated by trials.

The full engineering for Car Dumper 2 upgrade across mechanical / structural / civil / electrical disciplines was delivered for 19,500 hours, a PF (productivity factor = budgeted hours/actual hours) of 1.33. While this result is due to a number of factors, the use of Concerto is recognised as significant amongst them.

Concerto has proven of substantial value for this complex and fast paced engineering project. It has provided a strong and stable tool on which to set and apply a detailed “level 4” working plan.

Chris Turnell, Engineering Manager, July 2007

Leading from the Future - as it wants to emerge

How Descartes got it wrong: I am, therefore I think

In the use of any of the tools of continuous improvement such as TOC, Lean and Six Sigma, it is often the case that the results are substantially below what they are capable of delivering. Why is this the case? Could it be that thinking alone is not enough? To quote Einstein’s famous dictum: "The problems that exist in the world today cannot be solved by the level of thinking that created them"

What exactly did Einstein mean when he said that?, and what implications does such a thought have not only for ourselves, but also for the groups we work with on a daily basis, the organisations of which we are associates and the communities in which we live?

The first step in the journey of superior performance begins with the dawning of what we might call rational consciousness – when we are able to suspend our habitual judgments about the world as it presents itself to us and to pay attention to the interconnections that exist between the myriad of parts. We build new mental models based on data that disconfirms our existing world view. This way of operating and knowing is the very foundation of the scientific method. The knowledge is explicit and we can draw it in a process diagram or measure it on a graph. The instrument we use to access this level of knowing is the open mind.

There are many tools within the kitbag of continuous improvement to improve processes: Drum-Buffer-Rope, SMED, Five S, DMAIC, JIT, PMBoK®, CMSS, DFSS, EVMS, Critical Chain (CCMPM) and sometimes it seems an acronym for every man, woman and child ever born!

The trouble with thinking at this level is that it takes no account of what Deming, in his system of profound knowledge, referred to as "The Psychology of People, Society and Change". When we change a process, we often think of it in Newtonian terms, as if the change were analogous to kicking a stone: "If I apply a certain amount of force, in a certain direction, the stone will move at a certain calculated speed and then come to rest in a particular location" – all able to be computed to whatever number of decimal places suits the change agent. People however are different, and if one were to kick a colleague, subordinate or peer, the result would be far less likely to predict and we don’t recommend experimenting! The basic relationship that exists at this level of understanding is I-It, which reduces the relationship to one between subject and object, deprived of the richness of the realm of the human heart, and the field of emotional intelligence and knowing.

Social systems do not behave as deterministic machines – we cannot define our current reality through cause and effect alone, and neither are we able to construct a future of our choice through the application of reason alone. There is now ample evidence that as a species our very brain physiology gives us a predisposition for strong emotive connections. In a recent survey documented in the Sydney Morning Herald, it noted that despite our ever increasing affluence, we were not, as a nation, more happy. What was truly interesting about the survey was that people, when asked about what it was that made them happy, recorded that the quality and density of their relationships had a direct correlation to their level of happiness.

Thus, in order to yield the benefit of the very powerful tools of process engineering mentioned above, a necessary condition is to open the heart: to listen empathetically to the emotional effect of the changes being called for, to suspend judgment and cynicism such that the authentic voice of human experience can be heard.

As an example, it is one thing to quote and intellectually understand Deming, when he says "The object of any component is to contribute its best to the system, not to maximise its own production…some components may operate at a loss themselves in order to optimise the whole system…" and yet quite another to understand the feelings generated in doing so. How does the manager feel when all measures point toward making his system look good? How does a worker feel if asked to stand down in the name of the greater good? One can get easily caught in the emotional crossfire of the competing demands of waste elimination and the inherent need of any system to have built- in sprint capacity.

Breaking the idea that activity is directly related to value creation has a deep emotional consequence and the structure of our attention needs to move beyond what Buber characterised as I-It into I-You – in other words standing in the shoes of the person with whom we are interacting and feeling their emotions: joy and sorrow, pleasure and pain.

Emotional intelligence is however not enough if the objective is to perform at the level of our highest potential. We must dive deeper into the question of what it is that motivates us in our core? To access this part of ourselves we must think not about being players in the orchestra, or even the conductor of the piece, but rather as the composer herself! We must turn the focus of attention inward to the source of creation and ask the two most important questions anyone ever faces: who is my Self and what is my Work. Note that the word Self is capitalised, as it implies our higher self, as so profoundly expressed by Buber:

"The free man is he who wills without arbitrary self will. He believes in destiny, and believes that it stands in need of him. It does not keep him in leading strings, it awaits him, he must go to it, yet does not know where it is to be found. But he knows that he must go out with his whole being. The matter will not turn out according to his decision; but what is to come will come only when he decides on what he is able to will. He must sacrifice his puny, unfree will, that is controlled by things and instincts, to his grand will which quits defined for destined being."

Acting from this place, the place of highest potential, we summons the future into being as it wants to emerge.

I have long been a fan of the crew from the Sloane School of Management at MIT in Boston. Perhaps the most notable of their faculty is Peter Senge, author of The Fifth Discipline and advocate of the building of the "Learning Organisation". Last year I read a remarkable book co-authored by Senge, C. Otto Scharmer, Joseph Jaworski and Betty Sue Flowers called Presence: An Exploration of Profound Change in People, Organizations, and Society. In May of this year one of the co-authors of Presence, C Otto Scharmer finished his seminal piece of work, nine years in the making, called Theory U: The Social Technology of Presencing. If you are interested in exploring the ideas of leading from the future as it emerges, I cannot recommend these two books highly enough.

David Hodes

Reviews:

David Hodes speech at the

Australian Reporting Awards

On behalf of TOCCA I would like to say how happy I am to be associated with the ARA in sponsoring this first award for reporting on the management of Knowledge Capital.

If it is true that to a large extent our behaviour mirrors the way we are measured, then the work being done by the ARA ensures that reporting on those measures is developed to a very high standard. More than that though, they are always at the vanguard of what is important in both the public and private sector, and over the years, they have been instrumental in developing high standards of reporting in categories such as for example, occupational health and safety and the environment.

In a world of increasing globalisation, we all, rich and poor, healthy and sick, face the very difficult challenge of literally ensuring survival as a species to the generations of our children, grandchildren and beyond.

To do this, we will have to develop, apply and lever our knowledge in ways that amplify benefits, mitigate risks and minimises harm. Providing a framework by which we can measure, communicate and manage our stock of knowledge – that capital which is the true wealth of nations, is a fundamental step in the right direction.

Thus, I applaud the ARA in taking the lead in not only introducing this new award to Australia, but making it the theme of this year’s activities. As a new category, we had seven entries this year. We encourage you all to consider entering this category next year. If you think developing your understanding of knowledge capital is expensive – try ignorance!

It gives me much pleasure to announce the finalists. They are BHP Billiton Limited and Westpac Banking Corporation. And the winner is Westpac Banking Corporation

CPA Master Class Session - Focus on Excellence

Presented May 2007

The CPA Master Class Sessions is one of the major events in the NSW Division's professional development calendar. Sessions are structured to give attendees tangible outcomes by way of skill development and/or takeaway action plans to tackle the key business challenges of the day.

TOCCA presented:

Constraint Accounting: Debunking the Myth of Product Cost

In an era of fierce competition, manufacturing firms need to have a thorough understanding of their cost structure and how that structure relates to pricing and product mix decisions. Activity-based and standard costing methodologies have been the traditional approaches: however, a more recent and arguably more successful global trend is the Theory of Constraints based Constraint Accounting.

This master class explored an alternative framework for management accounting based on the Theory of Constraints (TOC).

This session challenged the assumption that there is a direct relationship between the total activity expended on the creation of a product or service and its cost. It outlined how to apply the TOC, that asserts the idea that it is the contribution per unit of the scarce resource (constraint) that should be used to provide proper financial judgments and inform the measurement framework that guides the behaviour of management and staff to optimise return on investment.

Key learning outcomes

An understanding of how Constraint Accounting can be used in the judgment of the following:

-

Profit centre evaluation

-

Investment decisions

-

Product attractiveness

-

Customer attractiveness

-

Make or buy decision making

- Pricing

The 18 CPA attendees produced some healthy debate which made for an enthusiastic open minded learning session, noting that David Hodes' communicated a "good topic and solid presentation content."

COMPLEX PROJECT MANAGEMENT EVENT

Breakthrough Strategies for driving excellence in complex project delivery.

February 2007, Menzies Hotel Sydney

In today’s world of increasingly complex projects, project and resource managers are under ever increasing pressure to keep things running on schedule and within budget in an environment of high uncertainty and competition for scarce resources.

This highly interactive session showed a step-by-step guide to implementing Critical Chain multi program management. The workshop focused on how to unleash the hidden potential of your portfolio of Projects.

The following areas were covered:

-

The common negative effects of most projects

-

The Critical Chain methodology and how it can ‘tame’ uncertainty

-

How to implement critical chain buffer management techniques

-

How to establish a more coordinated approach to planning and managing uncertainty during execution.

The following otganisations attended the workshop; Masterfoods, AXA, EDS, CSIRO, DOD, Tenix, NSW Health and DMO.

The attendees gave Tocca an overall rating of 87%, the effectiveness of the presentation 80%, the communication ability of the facilitators (David Hodes and Peter Crossley) 93% and a score of 87% for the degree of their preparation and organisation,

The overall comment of the day for both presenters was that they were "very knowledgeable and thought provoking".

Upcoming Events:

Challenging the

Traditions of Manufacturing

Conference - CPA Australia

Melbourne, Sydney July 2007

Two Day Conference including Master Classes

Competition in the manufacturing industry has never been more fierce and margins are being squeezed by local and international competitors. In order to survive, manufacturers need to completely reassess their approach towards performance measurements, finance and cost management.

You will discover techniques for improving your business through a series of case studies, Master Classes and with the addition of a new round table discussion, attend this conference to:

-

Asses the impact and opportunities of the latest WTO and FTA negotiations

-

Hear about the success that leading organisations have had with six sigma and lean manufacturing

-

Optimise the supply chain to achieve greater results

-

Discover how offshore business activities could improve your bottom line.

Tasmanian Manufacturing Conference

"Process Innovation - The Imperative"

Country Club Casino, Launceston

18th -19th October, 2007

The 2007 conference builds on the success of the 2005 conference and highlights the importance of process innovation in driving global competitiveness and capacity for growth. This theme will dominate the conference with a focus on process innovation principles and techniques, sustainability, skills development and the use of Information and Communication Technology (ICT).

The conference provides an opportunity for innovative Tasmanian manufacturers to share their experiences and hear from nationally recognised experts on topics such as lean manufacturing, the theory of constraints, six sigma and sustainability. The conference program includes:

-

the choice of two half-day workshops on lean manufacturing, the theory of constraints, value stream mapping and management accounting - Thursday 18 October 2007

-

a pre-dinner function - evening of Thursday 18 October 2007

-

the conference dinner - evening of Thursday 18 October 2007

-

plenary and Special Interest Sessions - Friday 19 October

The conference also provides a unique opportunity for service providers, trainers, consultants and government agencies to interact with people from industry to better understand their needs.

Tasmania's Minister for Economic Development and Resources, will officially open the conference and attend the conference dinner.

PROJECT FLOW 2007

Philadelphia, PA, USA

September 6th - 7th, 2007

CONFERENCE HIGHLIGHTS

|

Keynote Address by Ever Flourishing Companies |

Keynote Address by Achieving Your Organization’s Highest Priorities |

| Success stories from wide range of organizations: | |

| Action Park Multiforma Grupo is a Spanish company that designs and constructs leisure parks.

Alna Software is one of the major providers of customized software solutions in the Baltic States. Delta Engine Maintenance performs Maintenance, Repair and Overhaul of aircraft engines for Delta and others. Erickson Air-Crane owns, operates, and maintains a fleet of heavy-duty S-64 Air-crane helicopters. LeTourneau Technologies has some of the world’s leading innovators in design, manufacturing, and implementation of oil/gas drilling, as well as mining systems. |

Marketing Architects is a national leader in direct response radio advertising.

Ogden C-130 is a part of Ogden Air Logistics Center that performs maintenance, repair, and overhaul of the C-130 Hercules aircraft for US Air Force and US Navy. USAF Warner Robins Air Logistics Center is the largest industrial complex in Georgia, employing a work force of over 25,584 civilians, contractors, and military members. A Leading Medical Device Manufacturer |

| Complimentary Pre-Conference Workshop: "Resource Management in Multi Project Organizations", September 5th. Networking Opportunities: Share ideas and develop contacts with progressive managers and executives from other organizations. 1:1 Discussion with Realization Technical Personnel: Our technical and field personnel will be available for 1:1 discussions to answer your specific questions. Philadelphia Landmark: The conference venue, Park Hyatt Philadelphia at the Bellevue, is one of Philadelphia's most luxurious hotels and landmarks in the downtown district. Situated on the famous "Avenue of the Arts", Park Hyatt Philadelphia blends old-world architecture with modern amenities. You will discover unparalleled refinement, comfort and service during your stay at this truly exquisite hotel. | |

The 4th Annual PMOZ:

Project Management Australia Conference

28th - 31st August - Conrad Jupiters Gold Coast

The 4th Annual PMOZ Project Management Australia Conference will take place between the 28th and 31st of August at the Conrad Jupiter’s Hotel, Gold Coast. TOCCA will present a Pre-conference Workshop titled “Creating business success exploiting Critical Chain Project Management (CCPM)”. The workshop starts at 09:00, finishes at 17:00 and will be presented by David Hodes. David was sufficiently motivated by his own commercial rewards employing this method in South Africa, that he has created a successful Australian business, TOCCA, around not only Critical Chain, but the application of its underlying principles to other areas of business.

On the 28th August, Day 1 of the conference, between 14:00 and 14:25, Peter Crossley will present “Using Critical Chain Project Management to Create a Successful NPD Organisation”. Peter is one of the most experienced implementers of Critical Chain into Australian organisations and will share his thoughts on how this PMBok™ recognised scheduling method can yield a significant competitive advantage, especially in the New Product Development arena.

Gavin Grant - Business Development Manager

Gavin is passionate about building awareness of the TOC body of knowledge that provides means for businesses to make more money with less effort.

Born in Zambia and schooled in Port Elizabeth (The friendly City of South Africa), his first seven years of working life were spent as an electronic engineer in a highly technical field within HP. From there he moved into the manufacturing business world with a specialist company focusing on Advanced Planning and Scheduling (APS) applications. It is here that he first encountered the TOC world and he has since mused for many years why this very simple but powerful organisational management philosophy has not yet become mainstream globally. Gavin has many years of experience in identifying and meeting customer requirements in ERP and other Manufacturing and Telecomms applications.

This passionate family man is thoroughly enjoying living on Sydney’s Northern Beaches and is determined to make a difference by building massive momentum toward the broader use of TOC as a means of changing the world for good! Keep your ear to the ground for a new TOC User organisation.

Back to top